Structure Characteristics and Applications

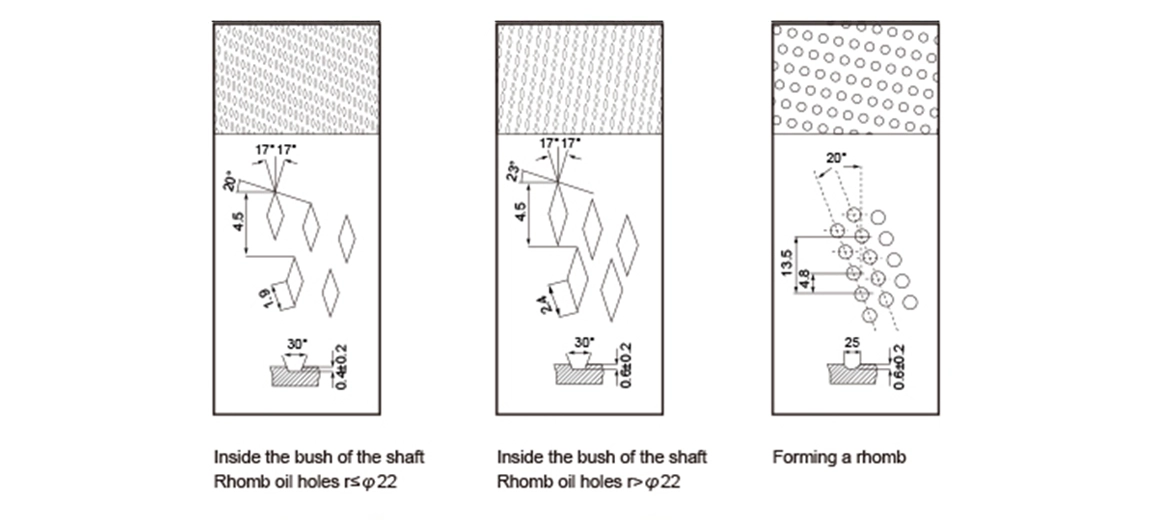

CBL-090 wrapped bronze bearing is made of tin-bronze CuSn8 with its surface punched with diamond oil sockets which are preserved for oil saving. It has good anti-fatigue, anti-erosion anti-abrasion and load capacity. The products are widely applied in conditions of heavy load but low running velocity, such as on agricultural, buiding and engineering machines.

Product Benefits

● Saving large amount of bronze material and save the working hours normally spent for lathing the bronze bushing.

● Compared with lathed bushings and roller bearings, it is lights and more cost-effective.

● Various holes and dents can be made on the frication surface for grease storage, prolonging the lubrication interval to 5 times as long as required by the bronze bushing.

● Extremely high load sustainability, especially suitable for coarse abrasion surfaces.

Standard products available: straight bushings, thrust plates and pressure bearings.

Material Structure

High-density bronze is rolled into shape or oil bags and oil holes are specially integrated into the inner surface to reduce the wearing and prolong the service hours. Besides, it has excellent anti-corrosion functions.

Technical Parameter

Tolerance

CBL-090 Tech. Deta

|

The use of parameters |

|

|

|

|

|

|---|---|---|---|---|---|

|

Parameters |

CBL-090 |

CBL-091 |

CBL-092 |

CBL-094 |

CBL-09G |

|

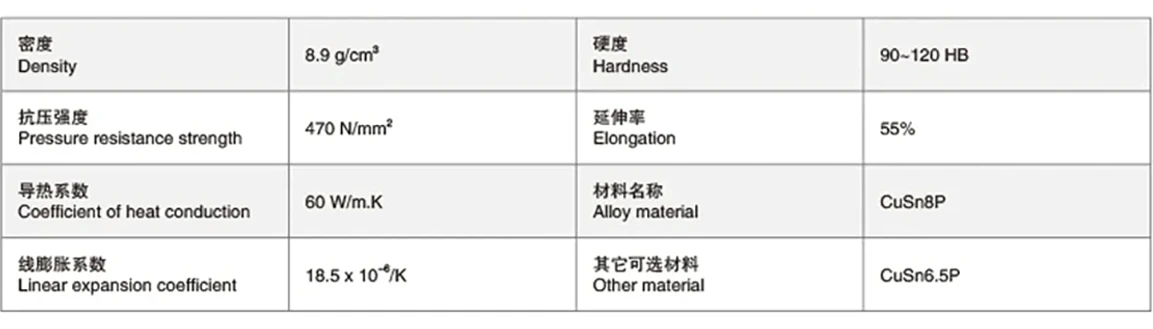

Density |

8.9g/cm³ |

8.4g/cm³ |

8.9g/cm³ |

8.9g/cm³ |

8.3g/cm³ |

|

Pressure resistance strength |

470N/mm² |

440N/mm² |

470N/mm² |

470N/mm² |

470N/mm² |

|

Coefficient of heat conduction |

60W/m.k |

71W/m.k |

60W/m.k |

60W/m.k |

58W/m.k |

|

Linear expansion coefficient |

18.5×10-6/K |

119.2×10-6/K |

18.5×10-6/K |

18.5×10-6/K |

18.5×10-6/K |

|

Hardness |

90~120 HB |

80~110 HB |

90~120 HB |

90~120 HB |

90~120 HB |

|

Elongation |

55% |

30% |

55% |

55% |

55% |

|

Alloy material |

CuSn8P |

CuZn31Si |

CuSn8P |

CuSn8P |

CuSn8P |

|

Other material |

CuSn6.5P |

|

CuSn6.5P |

CuSn6.5P |

CuSn6.5P |